ASH HANDLING SYSTEMS desein

Ash Handling Systems: Sl No Plant Client Ash Handling System– Each Unit Capacity Year of Initial Operati on Brief Description of System 6 Patratu Thermal Power Station – Units # 7 8 – 2x110 MW Bihar State Electricity Board 60 TPH 1976 Both fly ash and bottom ash are Continuously collected in wet form and ash slurry is conveyed tobottom ash handling system, which adopts a new process for handling clinkers in coalfired power plant boilers Following initial deliveries, further improvements have been made to the system, including seals that require no maintenance, reducing its cost of ownership Fig 1 Overview of dry bottom ash handling system Boiler Transition hopper Dry bottom ash handling system Improving Fly Ash Handling in Thermal Power Plants Short Intensive Training Course 1011th April, 2015 properly optimized fly ash pneumatic conveying system can cause significant amount of losses Power plant case studies and user problems for Fly Ash Handling in Thermal Power Plants Thapar Ash Handling Systems Ash is conveyed manually, mechanically, pneumatically and hydraulically Mechanical systems typically include submerged or dryflight conveyors, screw conveyors, and belt conveyors Pneumatic systems may be positive or negative pressure, as described laterFundamentals, Troubleshooting Maintenance of Ash In thermal power plants, we use lot of coal for power generation The coal has high amount of ash content, so these power plants generate lots of ash content so we need a high efficiency system for handling the ash The role of ash handling system plays a crucial role to maintain the environmental norms and following industry standardsAsh Handling System in Thermal Power Plant

Ash Handling System of a Thermal Power Plant

Requirement of Ash Handling System In Thermal Power Plant’s coal is generally used as fuel and hence the ash is produced as the byproduct of Combustion Ash generated in power plant is about 30 40% of total coal consumption and hence the system is required to handle Ash Estonian oil shale power plants’ ash handling problems H Arro, J Loosaar, T Pihu A Prikk Though the water used in the ash handling system circulates and in normal circumstances does not get out of the system, there is a It is the Balti Power Plant that has had many problems with excess water The increase of water is usuallyEstonian oil shale power plants’ ash handling problems Management of Ash Disposal Naresh, DN Additional General Manager, NTPC Ltd, Noida (UP), India ABSTRACT Management of Ash Disposal of coal based Thermal Power plant has to comply with the stipulations of the MoEF The environmental aspects are to be considered during planning and design stage of ash dyke it self The mainManagement of Ash Disposal GNDEC Ash handling system 1 Ash Handling Systems VVSPRADEEP 2 CONTENTS • ASH DISPOSAL • ASH HANDLING EQUIPMENT • ASH HANDLING SYSTEMS • ASH DISCHARGE EQUIPMENTS • SITE SELECTION 3 ASH DISPOSAL : 1 A large quantity of ash, is produced in steam power Ash handling system SlideShare For Ash Handling Plant (AHP) System Upgradation on Engineering, Procurement Construction (EPC) Contract Basis at Nabha Power Limited Nabha Power Limited (NPL), wholly owned by LT Limited has been successfully operating a 2x700 MW Supercritical Thermal Power Plant at Nabha Power Limited Microsoft

AIR QUALITY CONTROL SYSTEM(AQCS) Doosan Heavy

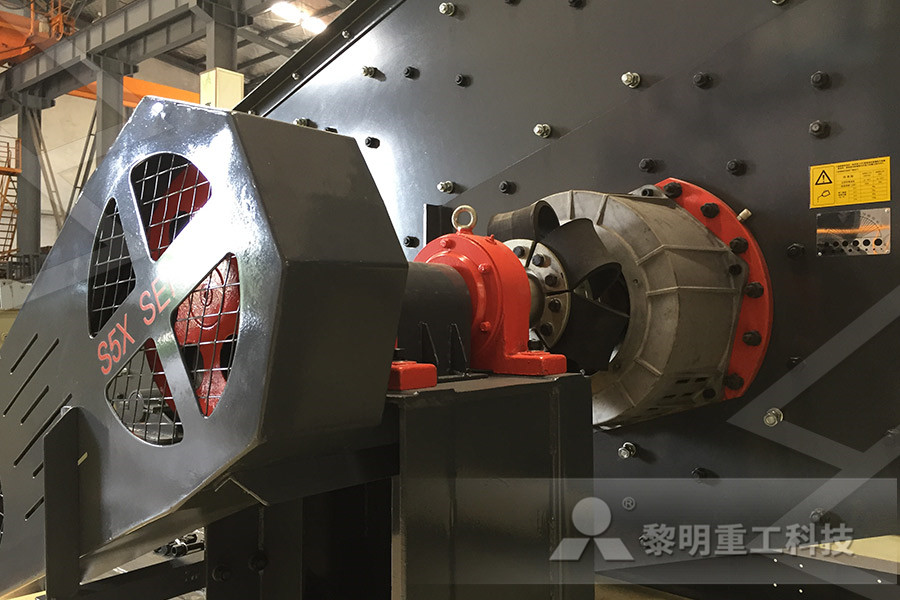

The Ash Handling System is an essential system for power plants, and a customized solution that handles ash from boiler, economizer, air preheater and ESP Doosan has many experience in various countries, and has maintained successful track records for more than 3 busting biomass in a boiler generates ash with high temperatures This ash (either bottom or fly ash) needs to be cooled and/or processed to a form that can be transported from the power plant Complete systems or specific equipment – ANDRITZ has the solution ANDRITZ offers complete solutions for biomass boiler ash handlingBottom and fly ash handling systems ANDRITZ Bottom ash handling System The bottom ash quantity is around 20% of the total Ash generation and there are mainly two types of bottom ash disposal systems Dry Type Bottom Ash Disposal; Wet Ash Slurry Disposal; Dry Type Bottom Ash Disposal: First of all we will discuss about the Dry type bottom ash disposal systemAsh Handling Plant Power4you "Power from Ash handling systems may employ different forms of pneumatic ash conveying or mechanical ash conveyors A typical ash handling system may employ vacuum pneumatic ash collection with ash conveying from several ash pick up stations and resulting in delivery to an ash storage silo for interim holding prior to load out for disposal or reuseAsh Handling Systems Nederman National Conveyors e Deployment of Helpers for Housekeeping of Ash Handling Plant Mill Reject system and Ash water recovery system 22 Location of the Plant Nabha Power Plant is located at Rajpura District accessible by road rail from Rajpura, which is in Punjab State The nearest broadgauge railway line is at Rajpura ChandigarhAMC for AHP Operation and Maintenance for Nabha

Ash discharge system 120 m3/h – Saxwerk

GE Boden Ash discharge system 120 m3/h PLANT REPORT SAX 1020 Download as pdf Saxwerk delivered in 2017 one discharge system for bottom ash to GE Power Sweden AB for ash handling system in Boden Saxwerk has delivered complete system with drawings for(DTE) to document the closure process for the Monroe Fly Ash Ba sin located at the DTE, Monroe Power Plant facility in Monroe, Michigan The permitted Monroe Disposal Facility includes a 79acre vertical extension (Vertical Extension) and 331acre fly ash basin (Ash Basin), as shown on Attachment 1MONROE ASH BASIN CLOSURE PLAN DTE Energy Coal handling plant • Coal • Unloading system • Conveyor system • Crushing system • Feeding system LAY OUT OF COAL HANDLING PLANT BTPS WT 1 WT 2 WT 3 B BR HOUSE B B Con11A/B C O A L Y A R D OCHP NCHP 20Sep13 Power consumption is approximately 225 watts Crushing systemCoal handling plant The Plant Miller Ash Pond will be closed by leaving CCR in place, with consolidation of ash to reduce the closure footprint to approximately 191 acres The pond will be dewatered sufficiently to remove the free liquids, and to an extent, to provide a stable base for the construction of the final cover system CCR will be consolidated within theAMENDED CLOSURE PLAN FOR ASH POND Alabama ash handling system in thermal power plant an overview thermal power generation capacity of india capacity of thermal power plants in india aug 2008 77198 mw 2012 (estimated) mw ash generation 130 million tons (approx) challenges in ash disposalOverview on Ash Handling System Pump Boiler

Dry Bottom Ash Handling Options and New Technology

Dry Bottom Ash Decision Analysis Technology AlternativesTechnology Alternatives 1 = Worst, 5 = Best Scale 15 ReCirc System SFC PAX VAX Criteria for Determing Technology Selection WT SC Total SC Total SC Total SC Total Water Usage/Availability 0 2 03050 5 0 Outage Time Available 0 5 04020 3 0 Total Installed CostTotal Installed Cost 0 1 0 5 0 3 0 3 0 A typical ash handling system may employ vacuum pneumatic ash collection with ash conveying from several ash pick up stations and resulting in delivery to an ash storage silo for interim holding prior to load out for disposal or reuse Pressurized pneumatic ash Ash Handling Systems Nederman National Conveyors GE Boden Ash discharge system 120 m3/h PLANT REPORT SAX 1020 Download as pdf Saxwerk delivered in 2017 one discharge system for bottom ash to GE Power Sweden AB for ash handling system in Boden Saxwerk has delivered complete system with drawings forAsh discharge system 120 m3/h – SaxwerkPipeConveyorSystempdf Unfortunately most of ash handling plant suppliers are not dealing with belt conveyors my opinion pipe conveyor can replace dense phase system as power consumption will be much less and dry transportation will be feasible In case of pipe conveyor cost will be much less than other conventional pumping (PDF) PipeConveyorSystempdf Prabir (DTE) to document the closure process for the Monroe Fly Ash Ba sin located at the DTE, Monroe Power Plant facility in Monroe, Michigan The permitted Monroe Disposal Facility includes a 79acre vertical extension (Vertical Extension) and 331acre fly ash basin (Ash Basin), as shown on Attachment 1MONROE ASH BASIN CLOSURE PLAN DTE Energy

Biomass Properties and Handling Iowa State University

slagging and fouling, and (3) volatiles content Ash content is the mass fraction of biomass composed of uncombustible mineral material Grasses, bark, and field crop residues typically have much higher ash contents than wood Systems that are designed to combust wood can be overwhelmed by the volume of ash if other biofuels are used The Plant Miller Ash Pond will be closed by leaving CCR in place, with consolidation of ash to reduce the closure footprint to approximately 191 acres The pond will be dewatered sufficiently to remove the free liquids, and to an extent, to provide a stable base for the construction of the final cover system CCR will be consolidated within theAMENDED CLOSURE PLAN FOR ASH POND Alabama ample, a 500 MWe plant using coal with 25% sulfur (S), 16% ash, and 30,000 kilojoules per kilogram (kJ/kg) heat content will emit each day 200 metric tons of sulfur dioxide (SO 2), 70 tons of nitrogen dioxide (NO 2), and 500 tons of fly ash if no controls are present In addition, the plant will generate about 500 tons of solid waste and Thermal Power: Guidelines for New Plants tm 58116 technical manual electric power plant design headquarters,department of the army 20 january 1984TM 58116 Electric Power Plant Design WBDG